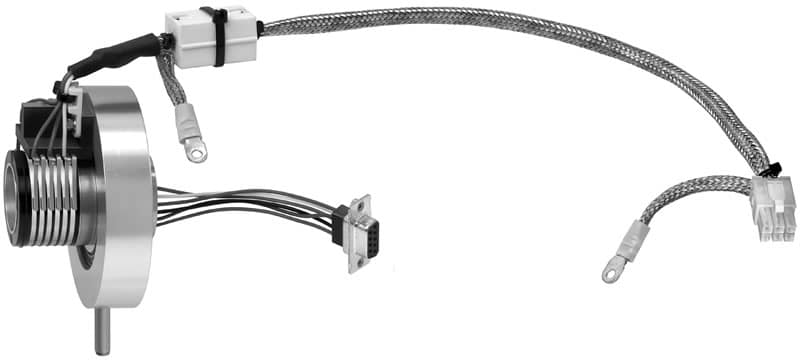

Our Best Cost & Delivery Stock Slip Rings can be modified to meet your electrical, mechanical and/or environmental specifications. Pictured are a few examples of Slip Ring modifications we performed to meet the specific needs of our customers.

Following is a list of some of the most common modifications Fabricast makes to its Stock Slip Ring Product Line.

- Addition of Stator Wire to Brush Blocks

- Longer Rotor Wires

- Addition of Connectors to Stator and Rotor Wires

- Alternate Thru Bore Sizes

- Modifications to Covers on Self Contained Slip Rings

- High Voltage Rings

- High Current Carrying Capacity Rings

- Vacuum Compatibility

- Different Rotor Wire Sizes (i.e. 22AWG, 18AWG)

- Brush Block Modifications

Modified Type 1986 Slip Ring with AMP® connectors added to standard rotor leads. Stator wires covered with copper braided shield and ferrite bead for EMI protection and terminated with AMP® connectors.

Modified Type 09816 Slip Ring built for a 3500 RPM centrifuge application. Six rings spaced further apart for three high voltage RF circuits. Coaxial and hookup wire stator leads with ITT Cannon® connectors added to custom brush block. Cover not shown.

Type 19012 Rotor with heat shrink, tie wraps, and Molex® connectors added to standard rotor leads.

Type 19012 Brush Block with twisted pair stator leads, tie wraps, part number coding, and Molex® connectors added to standard brush block.

Contact Fabricast for specialty modifications to fit your application.